Creating tools and experimenting with processes to upcycle various plastics.

With:

Dreamspace Collective: Jerushan Sritharan, Jathujan Mahendran, Sajeev Punithakaran, Gabishka Mohanalingam, Kiritharan Mahendran.

Trash For Trade: Abitharani Jeyachandran, Jayanthan Amalanathan.

With help & inspiration from fellow Dinasaurs Andy Quitmeyer, Michael Ang, and William Kennedy at Dinacon 2022

See also: Bendy the plastic heat bender, built by Brian Huang

THE HYDRAULIC PRESS

This press was built specifically for pressing heated acrylic scrap together for acrylic upcycling. The design was based around the materials at hand; it’s a modification of pre-existing designs like this one by petercd and this from Precious Plastics.

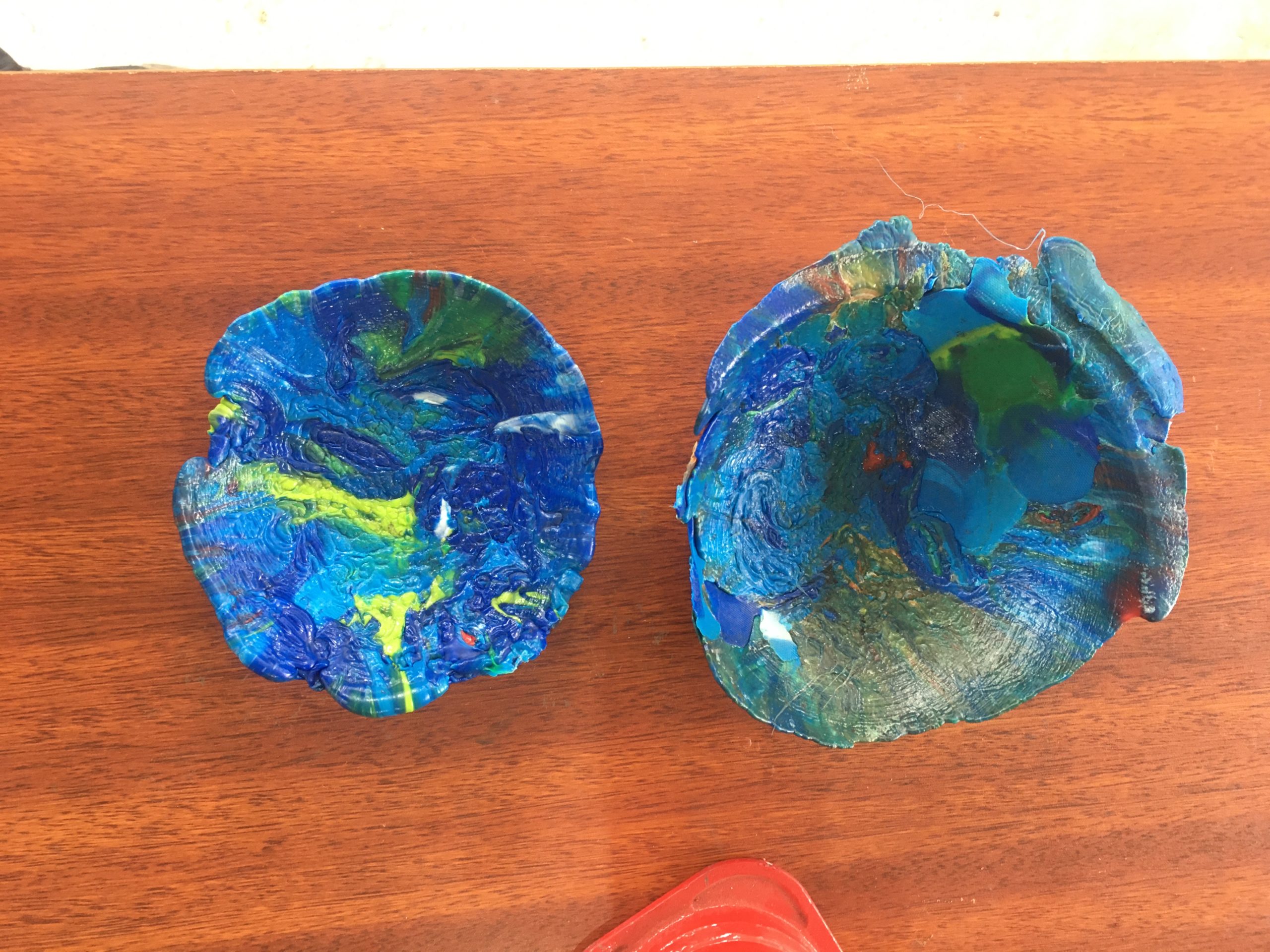

Upcycling Used Plastic into Raw Materials

Often people think of plastics shredding as the first part of this process, but it’s not a requirement – you can do this all without a shredder! The basic process is to apply heat to a pile of plastic, then apply pressure to turn them into flat sheets. Plastics like HDPE require minimal pressure, so they do not necessarily need a 8-ton hydraulic press (generally, the pressure supplied by a T-Shirt press will work fine). Acrylic, on the other hand, relies on high pressure after being heated in order to fuse together.

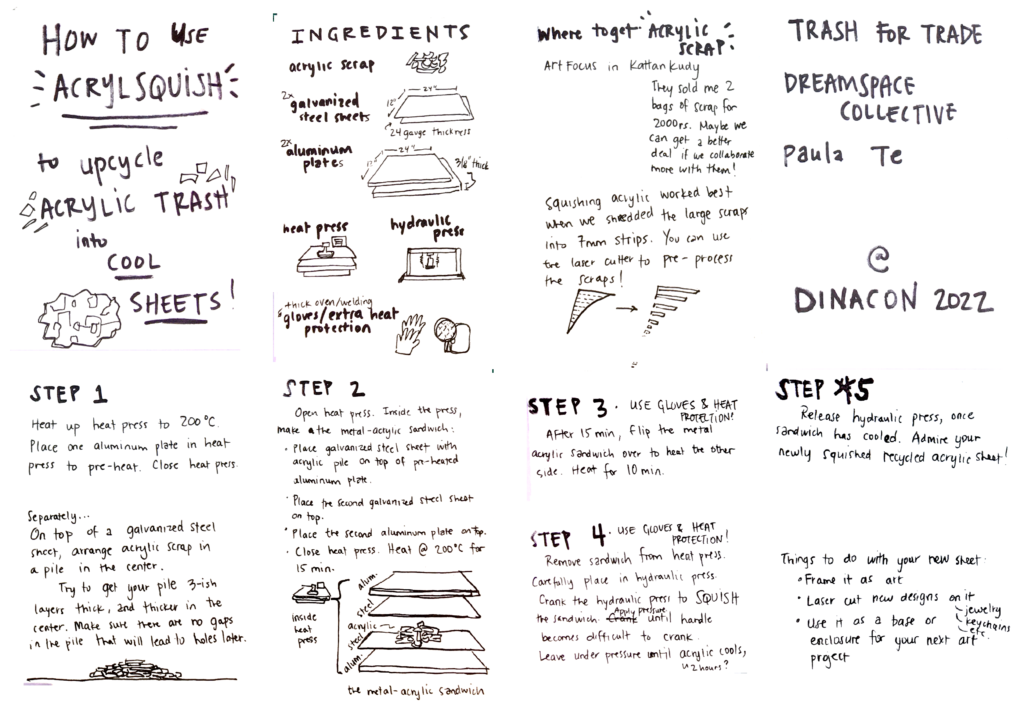

Check out the zine for upcycling acrylic with the hydraulic press:

Laser Cutting and Forming Plastics

Guides:

- How-to: Build a hydraulic press

- How-to: Upcycle plastics into sheets for laser cutting & more

- Zine: How to use the hydraulic press to upcycle acrylic

More Documentation:

- Building Acryl-Squish, a DIY hydraulic press

- Turning scrap plastic into new sheets

- Laser cutting and forming plastics

- Side projects: Teaching engineering drawing, Bike cue sheets, and a (failed) shade structure

References: